invest in innovations under implementation

We give an opportunity for industry stakeholders to invest and partner with us in the implementation of our projects that have been developed from our cutting edge research.

In this section, we highlight three projects that excel in technical and economical potential

Project CNF

This proprietary industrial process will turn MSW into hyper-affordable Gaseous biofuel, an organic soil conditioner and a liquid biofertilizer concentrate, allowing smallholder farmers to leverage organic fertility at 65% market price.

Digester monitoring system (dms)

The Digester Monitoring System (DMS) is InspCorp’s proprietary Remote Monitoring system designed to obtain performance-related data from a BioGas Digester.

FreshRain

Leveraging the power of rain to contribute to solving Africa’s Access to Potable fresh water crisis. FreshRain is InspCorp’s innovative smart rainwater harvesting and treatment system that is fully automatic.

combined nutrient and fuel process (project CNF)

The intersection between food security and solid waste management

1000 tonnes of solid waste end up in the streets of Mombasa every day. Only about 50% of the waste generated in the city is collected by the municipality. Unfortunately, this worrying metric is consistent across Kenya. The country’s biggest cities on average produce over 2000 tns/day of Solid Waste with only 45% of it collected. 55% of this uncollected waste ends up near residential areas resulting in environmental pollution, diseases, odours and significant GHG emissions.

On the other hand, fertilizers prices in Kenya have spiked 5 fold from their 2018 prices, affordability means sustainability and lack of sustainability means low productivity. But as if this is not enough, overuse of these same inorganic fertilizers has degraded productivity by 10 out of 30 bags per Ha for maize, some reports say.

So how are these two problems connected?

The Combined Nutrient and Fuel (CNF) process is InspCorp’s scalable and sustainable solution to improving food security and the management of organic municipal solid waste in Kenya. This proprietary process is designed to turn uncollected Organic Waste whose fate is often in the streets into hyper-affordable Gaseous biofuel, organic soil conditioner and a liquid biofertilizer concentrate, curbing environmental pollution and increasing agricultural productivity.

thus incentivizing the collection of trash.

These 2 chemical-free fertilizers which will be availed @ 65% of their corresponding market prices, ensuring Kenyan Farmers can grow food affordably and leverage the quality and safety of organic fertilizers.

In 1yr we plan to fully operationalise a 20 cbm CNF pilot plant within Likoni, Mombasa. This plant will add value to 7 Tonnes/month of organic waste locally generated in Likoni suburb while achieving product yields of 340 kgs LPG equivalent of Biogas/month, 960 kgs/month of soil conditioner & 1960 ltrs/month of biofertilizer concentrate. In turn generating an annual revenue of $119,850, representing an ROI of >40% on the pilot plant’s capex. The pilot plant will also curb 142 Tonnes/yr eq CO2 GHG emissions from the >50 Tns of organic waste whose fate would be on the streets of Likoni and at the same time provide 10 employment opportunities for the local residents.

Project Highlights

- Utilises Uncollected Municipal Organic Waste

- Potential 1.2 million Tns/Yr CO2-eq reduction

- Turns Waste to 3 Essential Products

- Generates hyper-affordable Organic Fertilizers @65 Market Prices

- High Impact, High Profitability – ROI >40%

“In 1yr we plan to fully operationalise a 20 cbm CNF pilot plant within Likoni, Mombasa”

Nick Mwanake

FOUNDER AND CEO

Project Highlights

- 24 hrs Gas Production monitoring

- Reactor Temperature Monitoring

- Wireless Remote Monitoring

- Performance Analysis

“Without a proper monitoring system, 2 out of every 3 BioGas Digesters will fail.”

a Proprietary InspCorp Innovation

Digester monitoring system

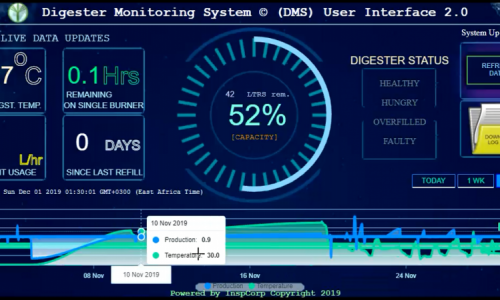

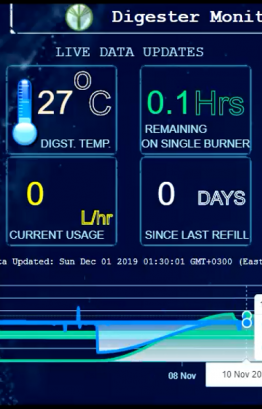

The Digester Monitoring System (DMS) is a Remote Monitoring system designed to obtain performance-related data from a BioGas Reactor. The BioGas Digester as any Bio-Reactor employs the use of complex colonies of micro-organisms that are very sensitive and delicate. Optimal performance of such microbial processes demands the maintenance of a very narrow range of operation parameters in addition to constant and consistent monitoring of the progress of the processes. The DMS is InspCorp’s proprietary innovation that aims at directly measuring the output of a BioGas Digester and its operation temperature to obtain critical data that will help the System Owner to understand the state of their reactor.

The DMS system is engineered with an ultrasonic sensor, a temperature sensor and the ESP8266 micro-controller WiFi Chip for remote data processing, analysis and transmission.

The relevance of this piece of innovation is that it allows for 24 hr monitoring of the digester giving the user the ability to discover how well their reactor system is performing on a specific type of feed-stock as well as allow them to detect when their Biogas digester is not on the right track. Through the data collected by the DMS, the system owner or hired maintenance will be able to detect how well the system copes to environmental or feedstock changes and thus will enable them to take appropriate measures in addition to assess the results of such mitigation measures.

The Ministry of Energy attributes common causes of failure of biogas systems to poor monitoring and maintenance. A feasibility study ‘Promoting Biogas Systems in Kenya’ by Shell International in 2007 revealed that ‘a high proportion of the Biogas Digesters in the country operated below capacity, were dormant or in complete disuse after construction.’ The same report revealed that only 30% of 2000 newly constructed BioGas Reactors were operational. This shows that without a proper monitoring system, 2 out of every 3 BioGas Digesters will fail. An opportune technology gap thus exists which creates a stable and lucrative niche market for InspCorp’s DMS technology following the apparent need displayed by the highlighted statistics. This market estimated at 20,000 currently existing digesters is bound to expand steadily as the uptake of small scale biogas systems increases.

Every DMS unit is assembled at InspCorp’s premises and is tailored for the user’s installation.

“FreshRain employs a chemical-free 5-stage filtration process with UV treatment to produce fresh-tasting natural rainwater that is 100% free of microbes and chemical additives.”

Project Highlights

- Computer-controlled rainwater harvesting with a smart self-cleaning routine

- Smart Monitoring

- Live Capacity Updates

- Meterological Tracking

FreshRain

a smart, scalable, turnkey roof-based rainwater harvesting solution

In Kenya, more than 50% of the population does not have safe water. According to a report by “Water.org” the number stands at around 29 million Kenyans without access to potable water. In Mombasa, Kenya, the crisis is even worse where a demand of 200,000 m3/day is only met with a supply of about 35,000 m3/day. Consequently, more than 80% of Mombasa’s 1.2 million residents face severe challenges with accessing clean drinking water.

Roof-based rainwater harvesting (RRWH) with adequate storage has the potential to significantly mitigate this problem in Mombasa County. A report by the Coast Water Services Board, the official authority for water matters in Mombasa, estimated a potential annual yield of 2.3 to 23 million litres of water if RRWH was implemented at a municipal scale. However, the same report cites that large-scale interventions to tap into the rainwater harvesting potential in Kenya have often been unable to get past the piloting stages. In addition, while rainwater often meets WHO’s physical and chemical thresholds for potable use, as the same report notes, its biological parameters are likely to fall short of the safety limits due to contamination by faecal coliforms and other water-borne microorganisms.

FreshRain is InspCorp’s proprietary smart rainwater harvesting and treatment system that is fully automatic. The unit is a turnkey solution and is designed for domestic and light commercial use with a treatment capacity of 250 LPH. The system can be scaled and tailored according to diverse water demands including the daily demand for treated water and the size of the raw water reservoir tank according to the available water harvesting capacity.

FreshRain employs a chemical-free 5-stage filtration process with UV treatment to produce fresh-tasting natural rainwater that is 100% free of microbes and chemical additives.

Our Engineers can size your system requirements and potential harvesting capacity based on your location and offer a complete standard solution from the harvesting area to the reservoir tank. Reach out to us for a quote on a comprehensive tailored solution.

Applications: Households, Schools, Hospitals, Commercial buildings, Hotels and Restaurants.

how to invest

we give you the opportunity to be part of the solution

A good partnership goes a long way. We believe in sharing our dream with like-minded visionaries who are looking for fresh and innovative ideas. Through our InspCorp-Investor partnership plan, we offer individuals or companies the opportunity to invest in any of the highlighted projects. The resources obtained will enable us to scale the particular project and maximisse its intended impact. In addition to supporting our vision, the InspCorp-Investor partnership plan will enable the investor to negotiate a lucrative return on their investment.

Our partnership process first begins with the simple form below. It will only take a few minutes, promise. Tell us which project has caught your eye and we will get back to you with the details on the investment plan and the opportunities available for that particular project.

Let’s fill the form and take our partnership to the next level!

inspcorp-investor partnership form

Please fill out the form below to let us know which project has caught your eye.

We look forward to being partners in the solution!

As iron sharpens iron, so one person sharpens another.

solomon

Location

InspCorp House

Shelly Beach Rd, Likoni

P.O. Box 85663-80100, Mombasa, Kenya.

Hours

We are open Monday to Friday, from 9:00 am to 5:00 pm and on Saturdays from 9:00 to 1 pm.